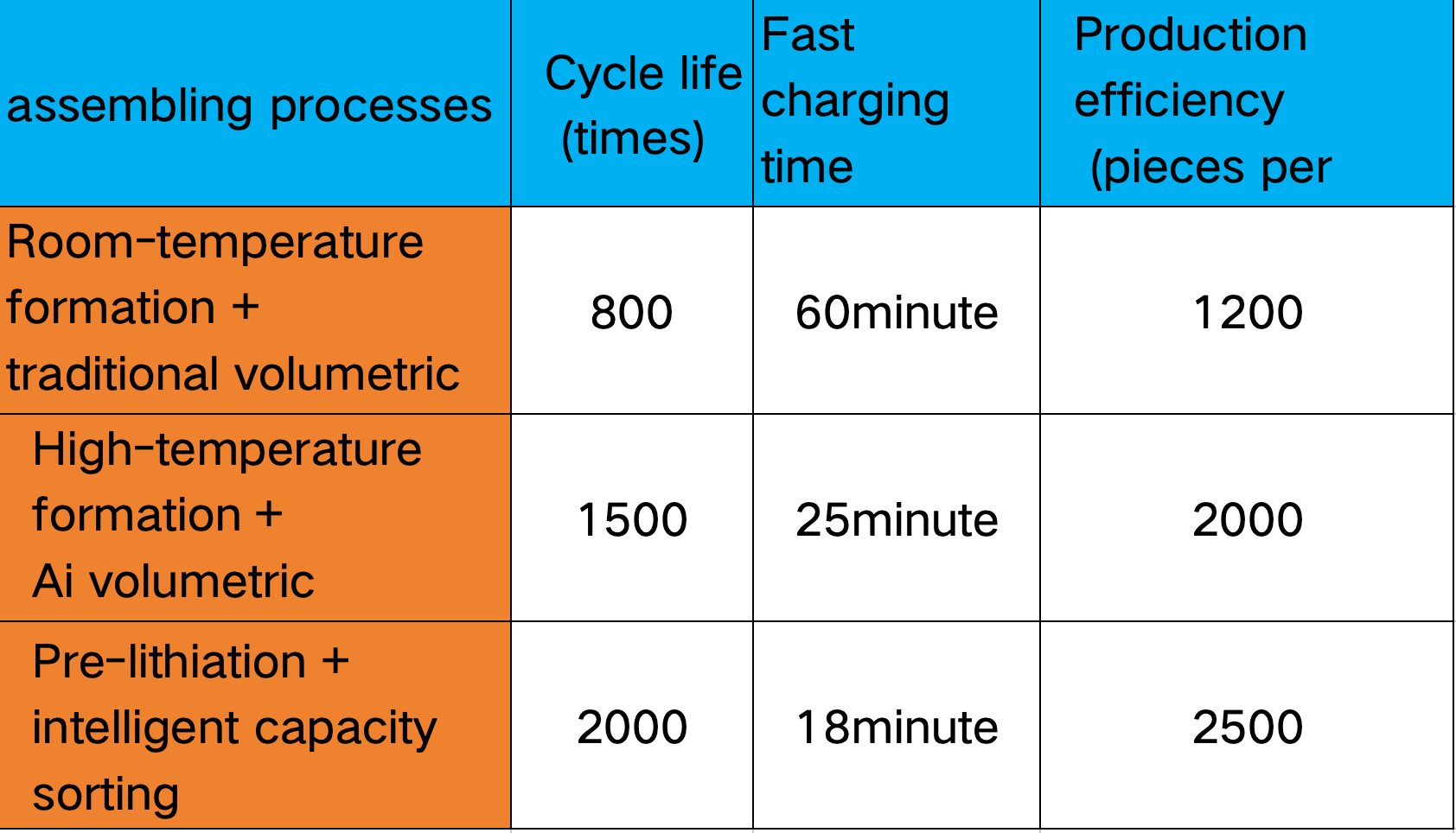

I. FormationFormation is the "moment of creation" for lithium batteries. Through precise control of current and temperature, it weaves a nanoscale "protective net" — the SEI film — on the surface of the negative electrode. This film, with a thickness of only one-thousandth of a hair (approximately 50-100 nanometers), can insulate electrons while conducting ions, earning it the title of the battery's "skin." 1. The Race Against Time for SEI Film During the formation process, solvent molecules in the electrolyte (such as ethylene carbonate) undergo a reduction reaction on the surface of the negative electrode, forming the main components of the SEI film: LiF, Li₂CO₃, and organic lithium salts. This process is like building an igloo at the crater of a volcano — it is necessary to allow the reaction to proceed fully while avoiding excessive reactions that could cause the "igloo" to collapse. Laboratory data shows that when the formation temperature rises from 45°C to 65°C, the formation rate of the SEI film increases by 30%, but the amount of gas produced by side reactions also doubles, meaning a delicate balance must be struck between efficiency and stability. 2. The Duet of Pressure and Temperature High-temperature formation (e.g., 80°C) can reduce the viscosity of the electrolyte, increasing the diffusion rate of lithium ions by 50%. However, excessively high temperatures can cause the organic components in the SEI film to dissolve, which instead reduces battery life. Research by Honeycomb Energy has shown that using a "stepwise heating" process (pre-charging at 45°C first, then constant pressure at 60°C) can increase the ionic conductivity of the SEI film by 20% while extending the cycle life to more than 1,500 times. More ingeniously, by applying a pressure of 0.5MPa, the contact area between the electrode sheets increases by 40%, which not only reduces polarization but also lowers the volume expansion rate of the battery by 15%. 3. Prelithiation: The "First Pot of Gold" for Batteries Traditional formation consumes approximately 12% of lithium ions for the formation of the SEI film, which is equivalent to a new car burning 12% of its gasoline as soon as it leaves the factory. Prelithiation technology, by pre-implanting lithium powder or lithium foil on the surface of the negative electrode, ensures that the formation of the SEI film no longer consumes lithium ions from the positive electrode. After a ternary lithium battery adopted prelithiation, its first-cycle efficiency increased from 88% to 95%, which is equivalent to an凭空 7% increase in battery capacity. This technology has been mass-produced in CATL's Kirin battery, enabling the energy density of the battery pack to exceed 255Wh/kg.II. Grading: Giving the Battery a "Full-body CT"Grading is the "physical examination center" for lithium batteries. Through charge-discharge tests, batteries are classified into different grades based on parameters such as capacity and internal resistance. This process is like giving the battery a "full-body CT"; it not only screens out unqualified products but also ensures the consistency of the battery pack — which is crucial for the range of electric vehicles and the stability of energy storage systems. 1. The Three Levels of Grading Basic screening: Through 0.5C discharge testing, batteries with a capacity lower than 90% of the nominal value are eliminated. An energy storage power station that mixed cells with a 5% capacity difference saw its usable capacity drop by 40% after six months, demonstrating the necessity of grading. In-depth diagnosis: High-precision grading equipment (such as Zhijianneng's FGS system) can detect voltage fluctuations of 0.02%, identifying potential risks of micro-short circuits or lithium plating. BYD's Blade Battery, during grading, uses AI visual inspection and ultrasonic flaw detection to increase the yield rate to 99.95%. Intelligent prediction: The "Mengxi" system developed by the Shenzhen Institute of Computing Sciences uses full-stack AI technology to analyze formation data, reducing the grading time from 20 hours to 4 hours while controlling the capacity prediction error within 0.37%. This technology has been applied in CATL's production lines, saving more than 8 million yuan in energy costs annually. 2. The "Butterfly Effect" of Grading The battery pack of an electric vehicle usually consists of thousands of cells. If just one cell has a 5% lower capacity, the usable capacity of the entire battery pack will be pulled down to the level of that cell. Tesla's 4680 battery, through grading screening, controls the internal resistance difference between cells within ±2mΩ, increasing the cycle life of the battery pack from 200 times to more than 1,000 times. More cleverly, after standardized cylindrical cells are retired, they can be directly formed into energy storage battery packs without disassembly, with a secondary utilization rate 40% higher than that of prismatic batteries. 3. Future "Black Technologies" in GradingA laboratory is developing a "self-healing grading film"; when a cell has a tiny break, the internal nanoparticles will automatically gather to fill the gap. Huawei's tested "graphene-coated aluminum-plastic film" can increase the heat dissipation efficiency during grading by 50%. Once these technologies are mass-produced, they will completely change the rules of the grading game.III. The "Duet" of Formation and GradingFormation and grading are not isolated processes; their synergistic effect determines the final performance of the battery. For example, high-temperature formation (60°C) combined with AI grading can increase the fast-charging capability of the battery by 30% while improving production efficiency by 5 times. The following table compares the performance differences of different process combinations:

This synergistic effect is particularly prominent in the energy storage field. After an energy storage power station adopted high-temperature formation (80°C) and AI grading, the temperature difference of the battery pack dropped from 5°C to ±2°C, the cycle life was extended by 30%, and the cost per kilowatt-hour was reduced by 12%.

IV. The Evolution Path of Formation and Grading

1. Intelligence: AI algorithms will replace traditional experience to realize real-time optimization of formation parameters. For example, the "Mengxi" system developed by the Shenzhen Institute of Computing Sciences can predict battery capacity and automatically adjust process parameters by analyzing MES data and formation curves, increasing the production yield to 99.5%.

2. Greenization: Zhijianneng's "bypass series formation and grading system" feeds back the discharge energy to the power grid with a feedback efficiency of ≥80%, saving enterprises more than 6 million yuan in electricity fees every year. This technology has been widely applied in CATL's production lines.

3.Integration: Future formation and grading equipment will integrate prelithiation, pressure control and intelligent detection functions to realize the full-process automation from liquid injection to finished products. A "super formation cabinet" displayed in a laboratory can handle 2,000 cells at the same time, with production efficiency 10 times higher than that of traditional equipment.