Introduction

As one of the core technologies of the new energy revolution, the performance of lithium batteries directly determines the technological ceiling in fields such as electric vehicles and energy storage systems. In the manufacturing process of lithium batteries, the coating process of electrode sheets is one of the most crucial links that determine the energy density, cycle life and safety of batteries. In recent years, with the explosive growth of the new energy vehicle market, the limitations of traditional single-layer coating processes in terms of efficiency and performance have become increasingly prominent. As an emerging technology, the double-layer coating process has significantly enhanced the efficiency and quality of electrode sheet manufacturing through layered design and precise control, thus becoming a hot research direction in the industry.

The double-layer coating process has achieved an efficiency revolution in the manufacturing of lithium battery electrodes through layered design and precise control. Its comprehensive advantages in production efficiency, battery performance, and cost-effectiveness have been widely recognized in the industry. With the breakthrough of domestic equipment technology and intelligent upgrading, double-layer coating is expected to become the core process of the next generation of lithium battery manufacturing. However, further breakthroughs are still needed in device stability and material compatibility to support the research and development needs of higher energy density batteries.

Overview of Characteristics of Double Layer Coating Process

The core principle and process of double-layer coating technology

The double-layer coating process refers to sequentially coating two different types of slurries on a current collector to form an electrode with an upper and lower layer structure. The core lies in layered design: the bottom slurry focuses on the adhesion with the current collector, while the upper slurry optimizes the electrochemical performance (such as high specific surface area and low internal resistance). This layered structure is controlled by adhesive layering, which solves the interface failure problem caused by adhesive migration in traditional single-layer coating.

Taking the narrow slit extrusion double-layer coating as an example, the specific process is as follows:

1. Slurry preparation: Prepare bottom layer (high adhesion) and top layer (high activity) slurries separately, and control the deviation of solid content to be ≤± 0.3%

2. Substrate unwinding: Copper foil/aluminum foil enters the coating area after tension control

3. Double layer coating: By synchronously extruding two layers of slurry through a dual cavity die (such as the Xinyu SDC coating machine), the coating speed can reach 150m/min

4. Drying and curing: The hot air circulation system reduces the moisture content of the wet film to ≤ 0.5%, and precise temperature gradient control is required

5. Roll up detection: CCD imaging system real-time monitoring of surface density deviation (≤± 1%) and size alignment (± 0.4mm)

Technical advantages and efficiency improvement of double-layer coating process

(1) Breakthrough in production efficiency

1. Single layer molding: Traditional single-layer coating requires multiple coatings and drying, while double-layer coating reduces process time by 50% through a single molding

2. Equipment compatibility: Domestic double-layer coating machines (such as Jin Yinhe parallel equipment) support wide width (Max1600mm) and high speed (150m/min), increasing single machine production capacity by 30%

(2) Optimization of battery performance

1. Energy density improvement: The double-layer structure can increase the specific surface area of the polarizer by 20% and increase the capacity by 15%

2. Extended cycle life: Layered design of adhesive reduces interface stress, increasing cycle life to 1500 times

3. Enhanced safety: The bottom layer of high adhesion material can inhibit the growth of lithium dendrites, reducing the risk of thermal runaway by 30%

(3) Cost benefit analysis

1. Material utilization rate: Double layer coating reduces slurry waste (≤ 1%), and single piece cost is reduced by 8%

2. Equipment investment return: Domestic double-layer coating machines (such as those from Keheng Co., Ltd.) are priced 40% lower than imported ones, and the investment payback period is shortened to 2 years

Analysis of the influencing factors on the formation of uniform and stable coatings by double-layer coating process

Multi layer microstructure design of lithium-ion battery electrodes can improve performance, such as:

(1) By finely designing the polar layer hierarchy, a "high-speed channel for ions and electrons" is constructed to reduce the diffusion resistance of lithium ions and slow down capacity decay

(2) By regulating the gradient distribution of the porous structure of the polarizer, a high porosity structure in the upper layer and a high pressure density structure in the lower layer are achieved, perfectly balancing high energy density and super fast charging dual cores

For this reason, the industry has devoted a lot of time and research. There are reports showing that by configuring two different slurries and applying multiple layers, the performance of electrodes can be improved. Here are some specific examples of double-layer structure electrodes:

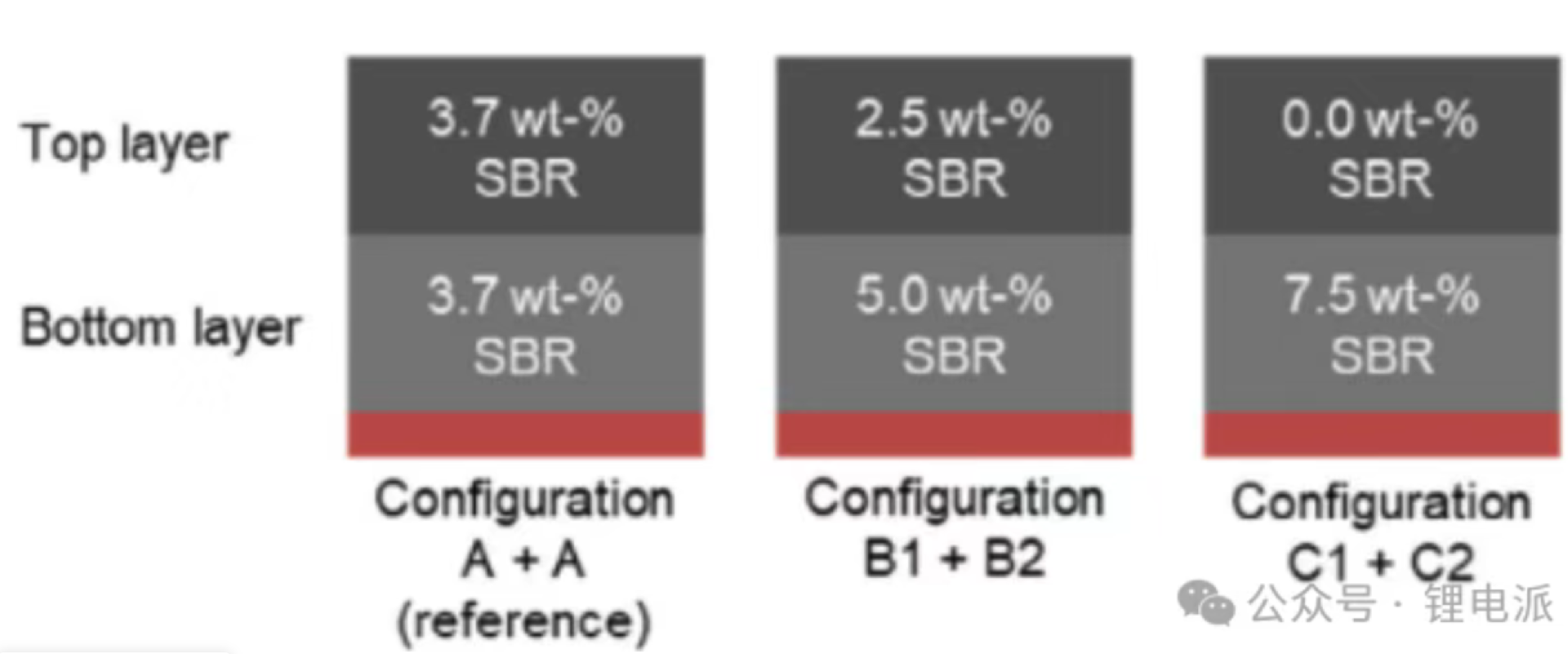

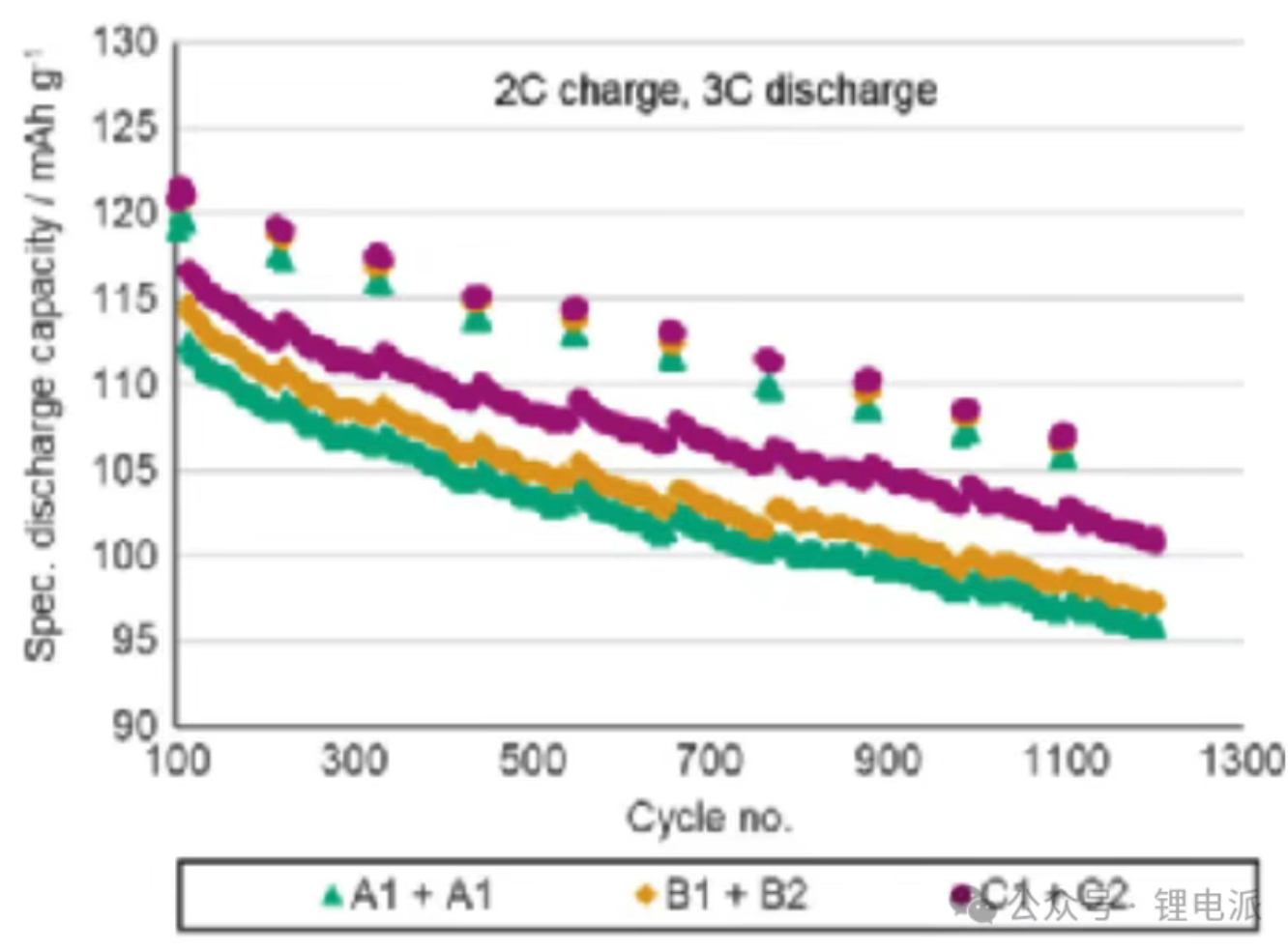

(1) Adhesive layer structure: During coating and drying, the adhesive will migrate to the surface due to capillary force. As the coating speed increases and the coating thickness increases, the adhesive migration becomes more severe during the drying process, which will further weaken the bonding force between the dressing and the current collector, and have a negative impact on battery performance. To solve this problem, the bottom slurry in the double-layer structure can be compensated with a high proportion of SBR.

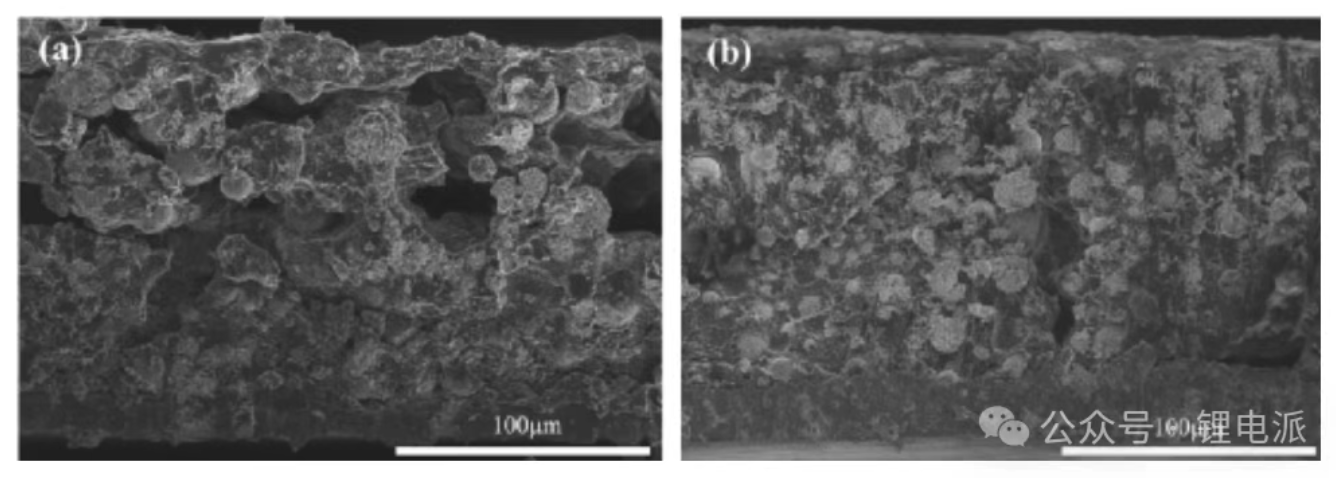

(2) Layered structure of conductive agent: Study the effect of the content of conductive agent in each layer of the two-layer structure LFP electrode on battery performance. The electrochemical performance test results show that, with a constant total conductive agent content of 5%, the electrode with a higher conductive agent content in the lower layer near the current collector exhibits better performance. As shown in Figure 2, compared with the higher content of conductive agent in the upper layer (Figure a), the higher content of conductive agent in the lower layer (Figure b) can form more conductive paths, lower the electron transfer resistance of the electrode, and improve the rate performance and cycling stability of the battery.

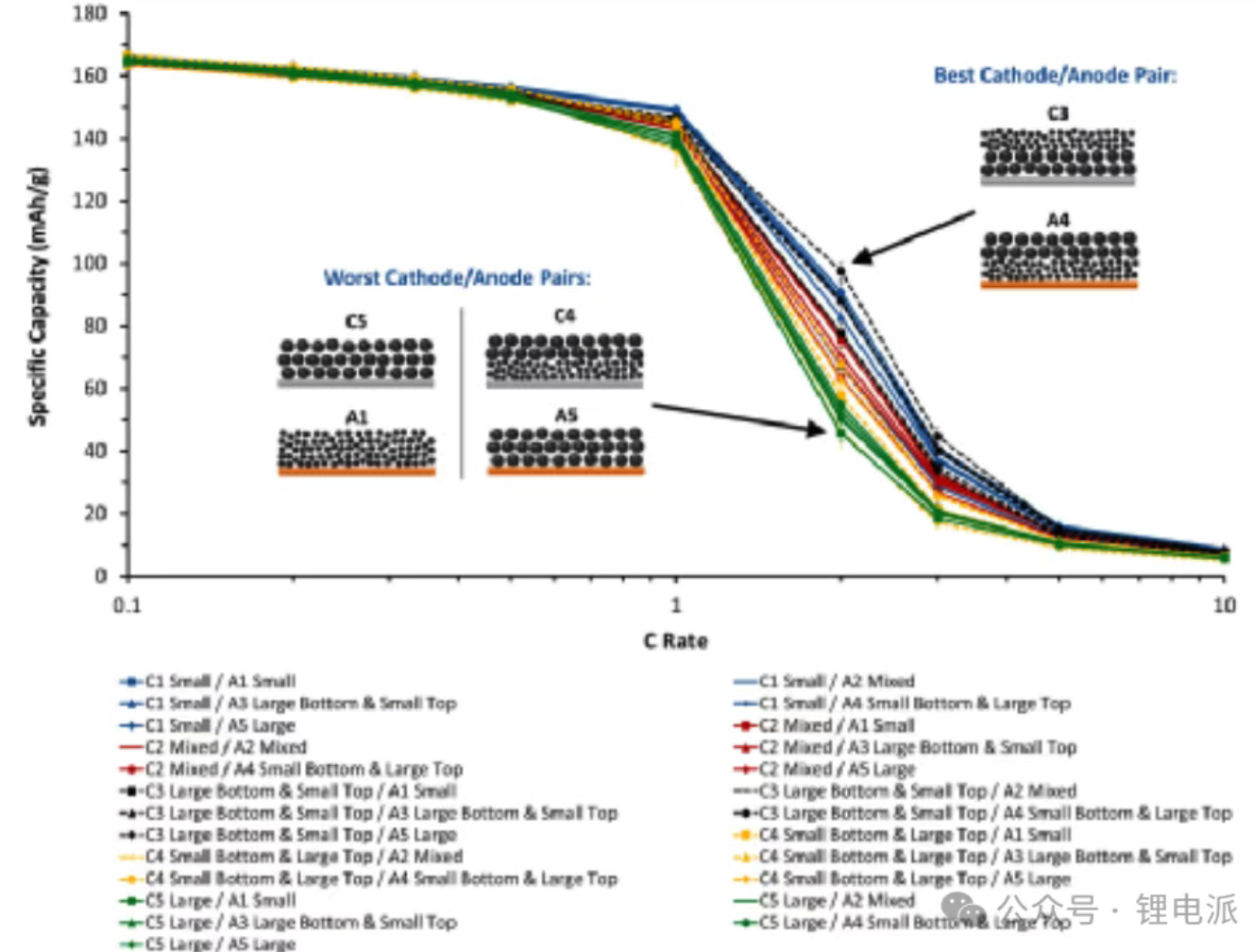

(4) Layered structure of porosity: The double-layer structure of the positive electrode with gradient porosity is shown in Figure 4. For Figure 4a, the porosity of the upper layer is greater than that of the lower layer. For Figure 4b, there is almost no difference in porosity between the upper and lower layers. The special structure of the electrode and the reasonable porosity distribution are conducive to the migration of lithium ions inside the thick electrode, thereby exhibiting better electrochemical performance at high current densities. Electrochemical performance tests show that the electrode in Figure 4a has higher initial Coulombic efficiency, superior cycling performance, and better rate performance.